Copper Wire

Overview/Description/Application

At Cirtek, we understand our customers need to maintain their competitive edge therefore it is important for us to find ways to reduce the impact of rising metal prices directly correlated to our gold wire bonding cost.

The increasing gold price has lead to increasing assembly raw materials costs. In order to mitigate and continue providing value to our customers, Cirtek has developed copper wire bonding technology since 2008.

Advantages

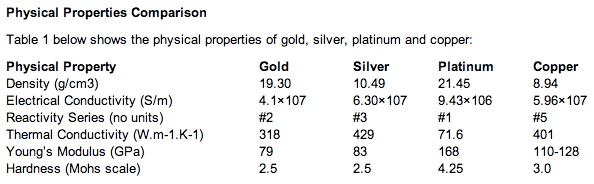

Between the two metals commonly used in semiconductors, copper stands out as being the best value-for-money and superior than gold in terms of electrical conductivity and thermal conductivity.

Process Highlights and Capabilities

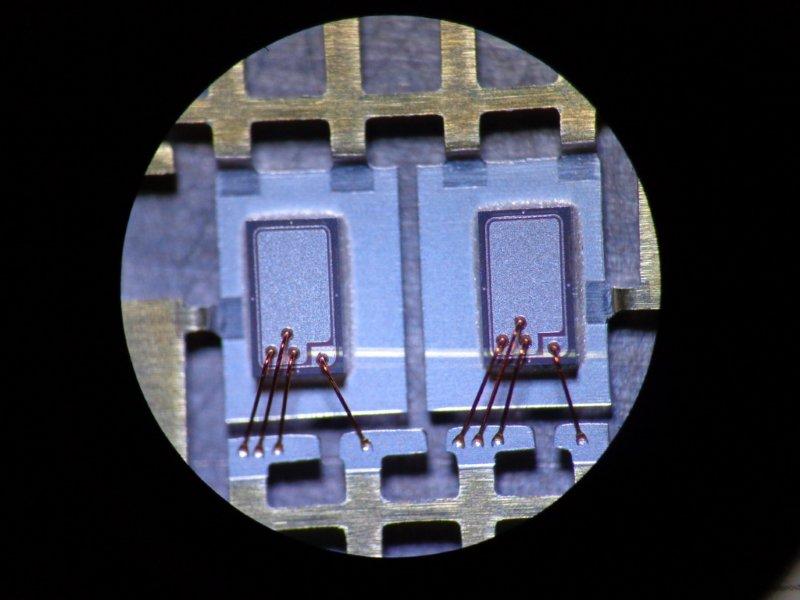

Copper is challenging to handle as compared to gold due to its reactivity to oxygen present in free air. Cirtek understands the criticality and takes extra steps from the initial storage, transport and handling of copper wire, to the actual bonding process all the way until the packages are fully molded and free from air exposure. Cirtek utilizes its copper conversion kits to accommodate copper wirebonding using inert gases that include N2 which act as absorber of oxygen, effecively shielding copper from exposure to air.

With the technology and measures in place, Cirtek has been able to achieve quality copper wire bonding capability and has shipped billions of units without reliability failures.

If you are interested to reduce unit costs and would like to try our copper wire bonding assembly, feel free to get in touch and we would be delighted to assist you.