Opto / LED

Overview/Description/Application

Manufacturing special devices such as Solid State Relays is a challenge to many semiconductor manufacturers due to the highly specialized process involved.

Cirtek has adapted and embraced the challenges of customizing and tailoring specific process flow per customer and product requirements.

Take in place the manufacturing of optocouplers that require the flow of signal from primary to secondary side while totally isolating both sides from electrical connection such as protecting delicate and costly circuitry from high voltage exposure.

.png)

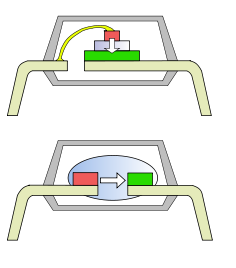

Top : Wire bonded unit with electrical connectivity from A to B.

Bottom : Total isolation from A to B. Connectivity possible only through light.

Advantages

Situations arise in electronic system design where signals and data need to be transferred from one subsystem or circuitry to another. In situations where the source and destimation are operating at a different voltage level such as a microprocessor operating on 5V DC and a triac switching on 110V AC, the two must be isolated from each other to protect the high costing microprocessor from potential over voltage damage. In cases such as this, optocouplers are necessary to continue data flow between two systems via light yet electrically isolate both from each other.

Process Highlights and Capabilities

By using multichip packaging techniques, Cirtek manufactures optocouplers by integrating LED die and phototransistors in a totally isolated substrate held intricately together by a special reflective coating allowing total internal reflection within the package.